air barrier behind electrical boxes Air leakage from electrical boxes, outlets, and wiring is a common cause of energy loss in commercial buildings. Air leaks from these areas can significantly drive up heating and cooling .

By using a non-consumable tungsten electrode and inert gas shielding, TIG allows for precise heat input and weld placement. Let’s explore the techniques, tools, and best practices that will elevate your TIG welding skills for sheet metal work. We’ll cover everything from equipment setup to advanced methods for tackling common challenges.

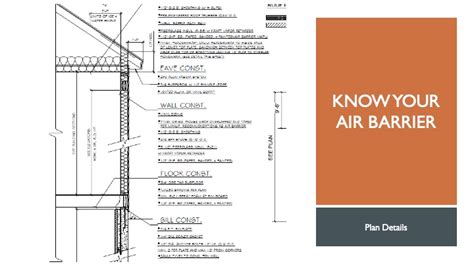

0 · iecc air barrier

1 · how to air seal electrical box

2 · ceiling mounted electrical box

3 · airtight metal electrical box

4 · airtight electrical box installation

5 · airtight electrical box code

6 · air tight electrical boxes

7 · air sealing electrical box installation

So, how to Use a MIG Welder Without Gas? Fortunately, you can still MIG weld metals without using protective gases. This method is known as Flux Core Arc Welding (FCAW) or Flux Core for short. In this method, you use a special welding wire known as a “flux core welding wire”. Similar to MIG’s electrodes, these flux core wires are consumable.

Air barriers are required behind tubs and showers on exterior walls to avoid air movement behind that space. The same applies to electrical boxes. Air-sealing electrical box requirements are found in the IRC: Table N1102.4.1.1 (R402.4.1.1). Under the electrical/phone box on exterior walls section, the code states: The air barrier shall be installed behind electrical and .Air can pass through tiny gaps around electrical wiring and holes in electrical boxes, carrying conditioned air into wall cavities and up into unconditioned attics or allowing air from .Air-sealed electrical and communication boxes that penetrate the air barrier of the building thermal envelope shall be caulked, taped, gasketed or otherwise sealed to the air barrier element .

browse our large selection of vapor seal boxes! Vapor Seal Series Features & Benefits (A) Patented (U.S. Patent #6,908,003 B2) flexible polyurethane flange available for sealing box to air/vapor barrier.

Air leakage from electrical boxes, outlets, and wiring is a common cause of energy loss in commercial buildings. Air leaks from these areas can significantly drive up heating and cooling .Air seal around all electrical wiring and electrical boxes installed through walls, ceilings, and flooring. Sealants (e.g., caulk, fire-retardant caulk, fire-rated spray foam, etc.) should be compatible with all adjoining surfaces and meet the fire .The air barrier shall be installed behind electrical or communication boxes or air - sealed boxes shall be installed.

Electrical/phone box on exterior walls The air barrier shall be installed behind electrical and communication boxes. Alternatively, air-sealed boxes shall be installed.

But the fastest, easiest and most effective way is to use the LESSCO AVB (Air-Vapor Barrier) Box. The LESSCO AVB Box air seals your standard plastic and metal electrical boxes in wood or metal construction using Romex, Armored .Air barriers are required behind tubs and showers on exterior walls to avoid air movement behind that space. The same applies to electrical boxes. Air-sealing electrical box requirements are found in the IRC: Table N1102.4.1.1 (R402.4.1.1). Under the electrical/phone box on exterior walls section, the code states: The air barrier shall be installed behind electrical and communication boxes. Alternatively, air-sealed boxes shall be installed.Air can pass through tiny gaps around electrical wiring and holes in electrical boxes, carrying conditioned air into wall cavities and up into unconditioned attics or allowing air from unconditioned garages and crawlspaces into living spaces.

Air-sealed electrical and communication boxes that penetrate the air barrier of the building thermal envelope shall be caulked, taped, gasketed or otherwise sealed to the air barrier element being penetrated.browse our large selection of vapor seal boxes! Vapor Seal Series Features & Benefits (A) Patented (U.S. Patent #6,908,003 B2) flexible polyurethane flange available for sealing box to air/vapor barrier.Air leakage from electrical boxes, outlets, and wiring is a common cause of energy loss in commercial buildings. Air leaks from these areas can significantly drive up heating and cooling costs, and compromise the integrity of fire-rated assemblies.Air seal around all electrical wiring and electrical boxes installed through walls, ceilings, and flooring. Sealants (e.g., caulk, fire-retardant caulk, fire-rated spray foam, etc.) should be compatible with all adjoining surfaces and meet the fire .

The air barrier shall be installed behind electrical or communication boxes or air - sealed boxes shall be installed.

iecc air barrier

how to air seal electrical box

Electrical/phone box on exterior walls The air barrier shall be installed behind electrical and communication boxes. Alternatively, air-sealed boxes shall be installed.

But the fastest, easiest and most effective way is to use the LESSCO AVB (Air-Vapor Barrier) Box. The LESSCO AVB Box air seals your standard plastic and metal electrical boxes in wood or metal construction using Romex, Armored cable, conduit or Low voltage applications.

Air barriers are required behind tubs and showers on exterior walls to avoid air movement behind that space. The same applies to electrical boxes.

Air-sealing electrical box requirements are found in the IRC: Table N1102.4.1.1 (R402.4.1.1). Under the electrical/phone box on exterior walls section, the code states: The air barrier shall be installed behind electrical and communication boxes. Alternatively, air-sealed boxes shall be installed.

Air can pass through tiny gaps around electrical wiring and holes in electrical boxes, carrying conditioned air into wall cavities and up into unconditioned attics or allowing air from unconditioned garages and crawlspaces into living spaces.Air-sealed electrical and communication boxes that penetrate the air barrier of the building thermal envelope shall be caulked, taped, gasketed or otherwise sealed to the air barrier element being penetrated.browse our large selection of vapor seal boxes! Vapor Seal Series Features & Benefits (A) Patented (U.S. Patent #6,908,003 B2) flexible polyurethane flange available for sealing box to air/vapor barrier.Air leakage from electrical boxes, outlets, and wiring is a common cause of energy loss in commercial buildings. Air leaks from these areas can significantly drive up heating and cooling costs, and compromise the integrity of fire-rated assemblies.

Air seal around all electrical wiring and electrical boxes installed through walls, ceilings, and flooring. Sealants (e.g., caulk, fire-retardant caulk, fire-rated spray foam, etc.) should be compatible with all adjoining surfaces and meet the fire .The air barrier shall be installed behind electrical or communication boxes or air - sealed boxes shall be installed.

Electrical/phone box on exterior walls The air barrier shall be installed behind electrical and communication boxes. Alternatively, air-sealed boxes shall be installed.

ceiling mounted electrical box

airtight metal electrical box

Sheet metal fabrication is a complex but vital process that involves various techniques such as stamping, bending, welding, and laser cutting. Each technique serves a specific purpose and is essential for producing high-quality sheet metal products with precision and efficiency.

air barrier behind electrical boxes|airtight electrical box installation